Motor Direction &Speed Control

Mastering Motor Control: A Deep Dive into Electric Motor Direction and Speed Controllers

Introduction

Whether you're building a robot, an electric vehicle, or an automatic window blind system, controlling the direction and speed of an electric motor is a fundamental task. This blog post will take you on a detailed exploration of electric motor direction and speed controllers, shining a light on the principles behind these essential devices and helping you to better understand their applications and functionalities.

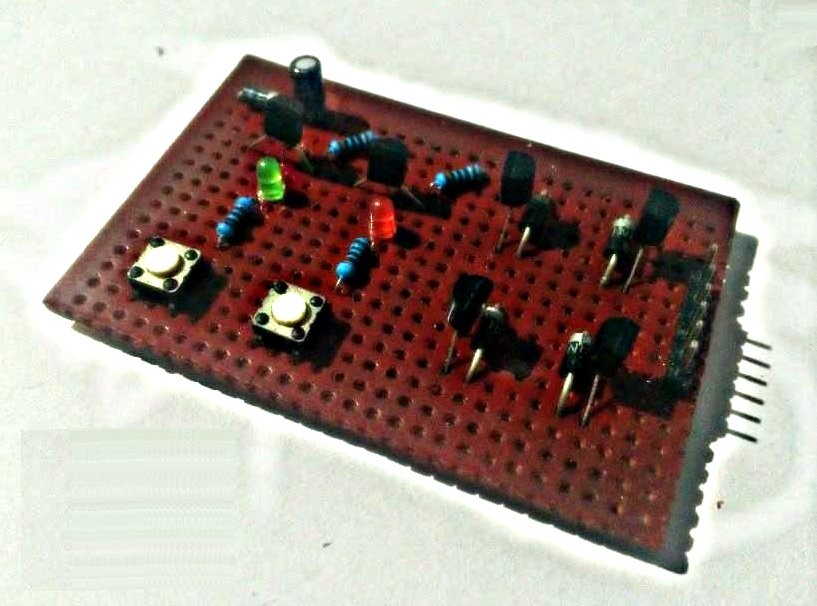

(Electric Motor Direction & Speed controller)

With this module, you can easily control the direction and speed of DC motors using an Arduino or simple push buttons. H-Bridge Configuration

The Basics of Electric Motors

Before we dive into motor controllers, it's important to understand the basic workings of electric motors. At their core, electric motors convert electrical energy into mechanical energy using the principles of electromagnetism. The two most common types of electric motors are AC (Alternating Current) motors and DC (Direct Current) motors.

Speed and Direction Control

The ability to control an electric motor's speed and direction is crucial in many applications. For instance, in a robotic car, you need to control the speed to manage how fast the car moves and the direction to determine whether it goes forward or backward.

Understanding Motor Direction Control

The direction of a DC motor is typically controlled by reversing the polarity of the current flowing through the motor. This is often accomplished using a device known as an H-Bridge, a circuit that can switch the direction of the current flow through the motor.

The H-Bridge consists of four switches or transistors. By controlling which pair of transistors are turned on, you can control the direction of current flow through the motor, and hence, the direction of rotation.

Deciphering Motor Speed Control

For DC motors, speed is primarily controlled by varying the voltage supplied to the motor. One common way to do this is through a method known as Pulse Width Modulation (PWM). PWM involves varying the amount of time the voltage is applied during a fixed period, effectively varying the average voltage supplied to the motor.

By switching the voltage on and off very quickly, the motor sees the 'average' voltage over time. If the voltage is on for most of the time, the average voltage is high, and the motor spins quickly. If the voltage is on for only a small fraction of the time, the average voltage is low, and the motor spins slowly.

Motor Direction and Speed Controllers

Motor controllers combine the principles of speed and direction control. They typically involve a microcontroller or other control system that generates a PWM signal and controls the H-Bridge. The duty cycle of the PWM signal controls the speed of the motor, while the H-Bridge configuration controls the direction.

Applications of Motor Controllers

Motor direction and speed controllers are used in a wide variety of applications:

Robotics: Robots often need precise control over their motor's speed and direction to move and interact with their environment effectively.

Electric Vehicles: In electric vehicles, motor controllers manage the speed of the vehicle and the direction, controlling whether the vehicle moves forward or backward.

Industrial Automation: Conveyor belts, lifts, and other automated machinery all need motor controllers to manage their operations.

Choosing a Motor Controller

When choosing a motor controller, consider factors such as:

The type of motor you are using (DC, stepper, servo, etc.)

The voltage and current requirements of the motor

The precision of control you need over speed and direction

The interface of the controller (analog, digital, I2C, SPI, etc.)

Conclusion

Understanding the principles of electric motor direction and speed controllers is key to mastering motor control in any project. By combining the functionalities of H-Bridge circuits and Pulse Width Modulation, these controllers offer precise control over the motors, making them indispensable in fields like robotics, electric vehicles, and industrial automation.

Posted by Ali Aslan at Friday 12th of May 2023 08:02:24 PM