Mini DVD CNC DIY

Mini CNC plotter

In the world of engineering and electronics, there is a constant search for new ways to innovate, improve, and create functional and accessible devices. One remarkable example of this is Engineer Ali's Mini CNC plotter project, which utilizes DVD parts to create a highly functional and affordable mini CNC plotter capable of drawing and cutting various shapes.

This will be a prototype, but once you manage to build it, you'll probably be able to build much larger and much more acurate printers. The principle is the same. We will use step motors to control the movement of the 3 axes of our machine.

CNC - What is it?

The system is based on controlling the movements of the working tool relative to the coordinate axes of the machine, using a computer program executed by a computer. In the case of a lathe, it is necessary control the movements of the tool in two coordinate axes: the X axis for the longitudinal displacements of the carriage and the Z axis for transverse displacements of the tower. For milling vertical displacements, corresponding to the axis Y. This servomotors are incorporated in the mechanisms of the carriage and the turret, in the case of lathes and in the table in the case of control also milling machine; depending on the capacity of the machine, this may not be limited only to three axes.

Step motor - What is it?

The step motor is an electromechanical device that converts a series of electrical impulses in discrete angular displacements, which means it is able to move a number of degrees (step) depending on your control inputs. The stepper motor behaves the same way as a (D / A) converter and digital-analog can be governed by impulses from logical systems. This motor has the advantages of precision and repeatability as positioning. Its main applications stand out as variable frequency motor, DC motor, brushless servomotors and digitally controlled motors.

The Mini CNC plotter project by Engineer Ali is the result of his extensive knowledge and expertise in the field of electronics and mechanical engineering. By reusing and repurposing old DVD parts, he was able to create a highly functional and affordable device that is capable of drawing and cutting various shapes with precision.

First of all we must open 3 DVD recorders to remove the motors and moving parts necessary for the construction of our machine. We must open them with care not to break the pieces we need. In the next picture we see the inside of a DVD recorder.

Simply unscrew the 4 screws marked on the image can extract the piece we need, an entire axis by a stepper motor. We can see in the image below the piece just removed.

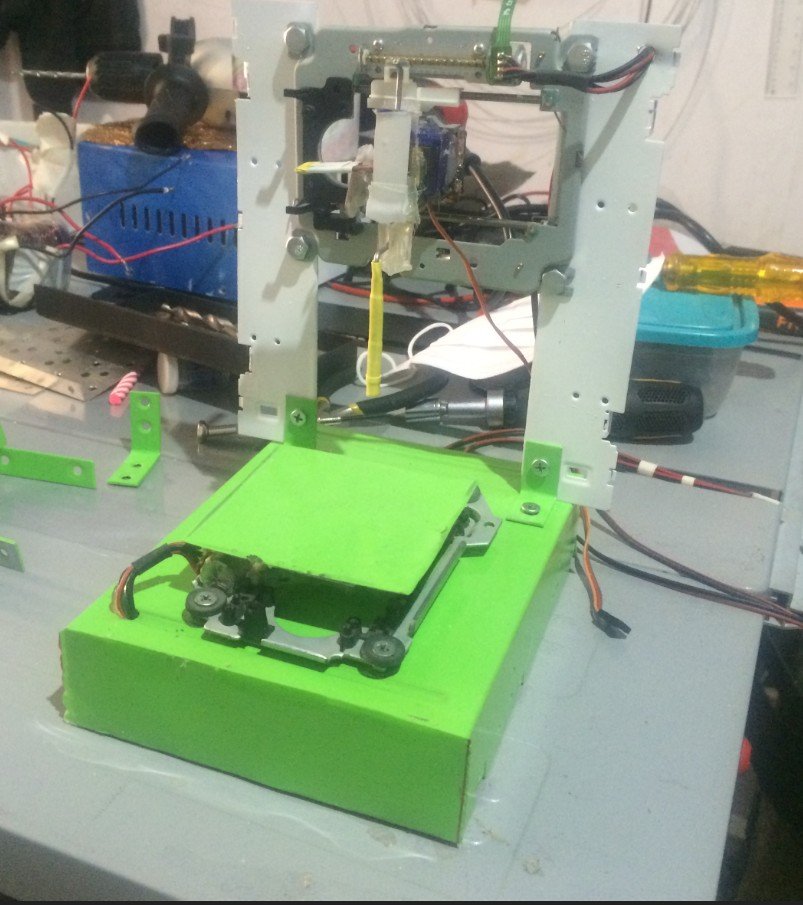

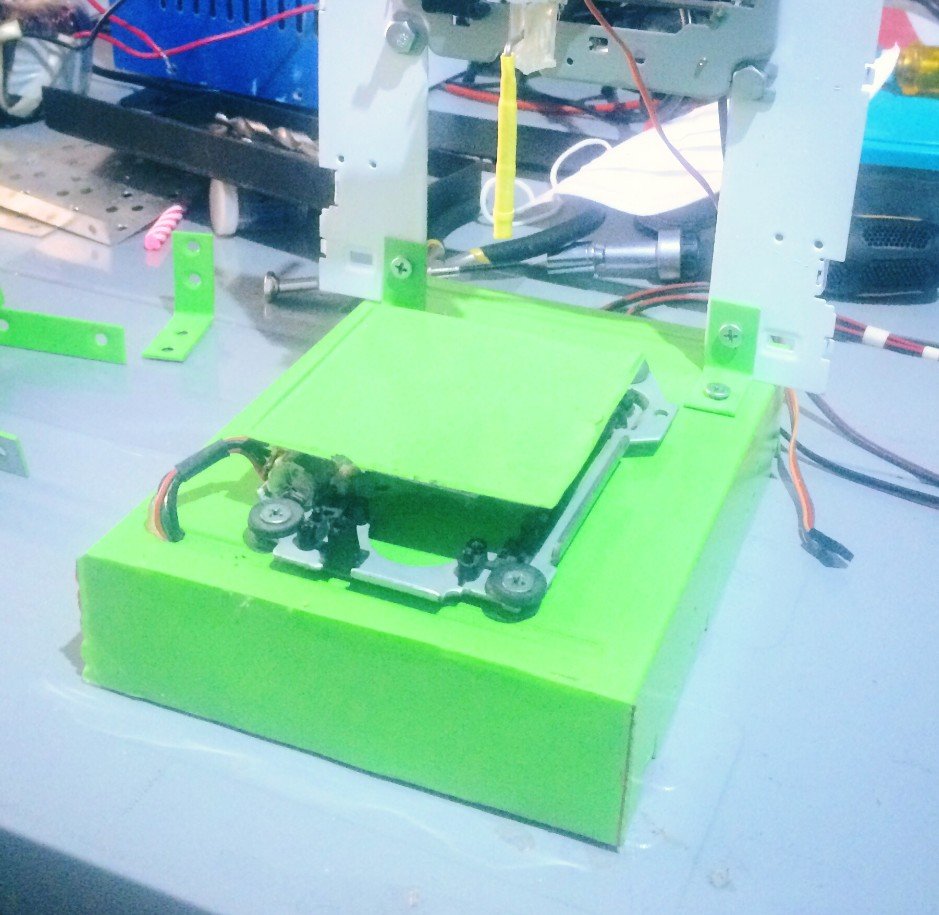

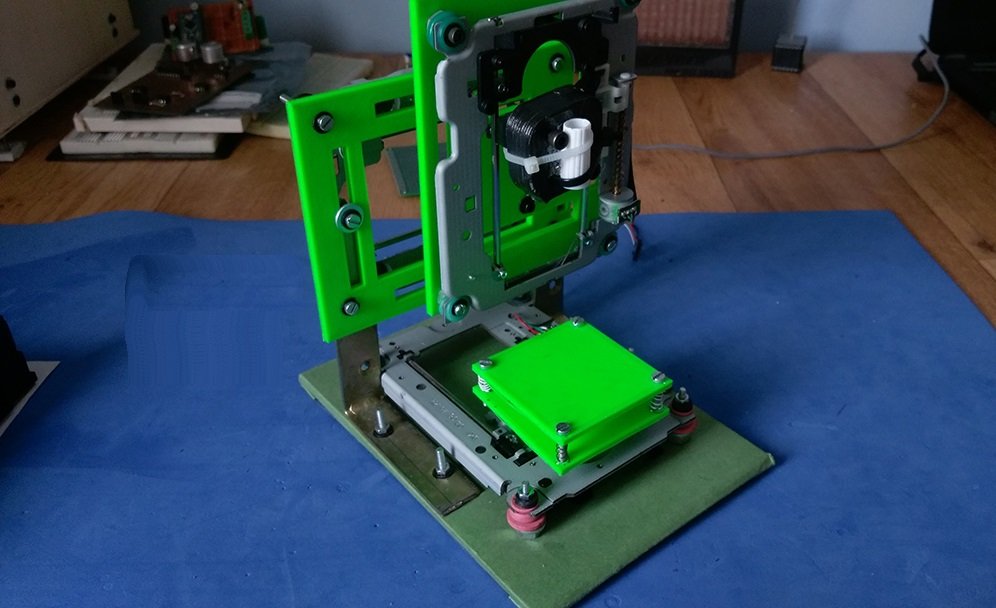

Now we have 3 axes we need, we build the machine itself. Before you start you can see my machine sizes in the image below.

That cut a wooden plate 12x17 cm will be our base. 4 holes will very focused in the right way to screw the first axis, which is the axis "y". We check that the holes in our plate match those of the shaft out and screwed recorders 4 screws.

The Mini CNC plotter project is an excellent example of how simple and affordable materials can be used to create remarkable and highly functional devices. This project is not only accessible to a broad range of people, but also an excellent starting point for beginners in the field of CNC and 3D printing.

The plotter is made from a DVD player and a few other commonly available electrical components, including stepper motors, driver boards, and a power source. This simple yet effective design allows the plotter to move the pen across its two axes with precision, creating highly detailed drawings and shapes on various surfaces.

This mini CNC plotter has tremendous potential, as it can be used for a variety of applications. From drawing and cutting shapes to etching and engraving designs on objects, this Mini CNC plotter project can do it all. It can be used in the field of art, design, and engineering, among many others, making it a truly versatile and valuable device.

One aspect that makes this Mini CNC plotter project especially remarkable is its affordability. It is not only affordable, but it also utilizes recycled materials, making it an excellent option for those interested in eco-friendly projects. The Mini CNC plotter project is an excellent solution for those starting out in the field of CNC and 3D printing, as it is a great way to learn the basics of the technology and experiment with the uses in a cost-effective and accessible way.

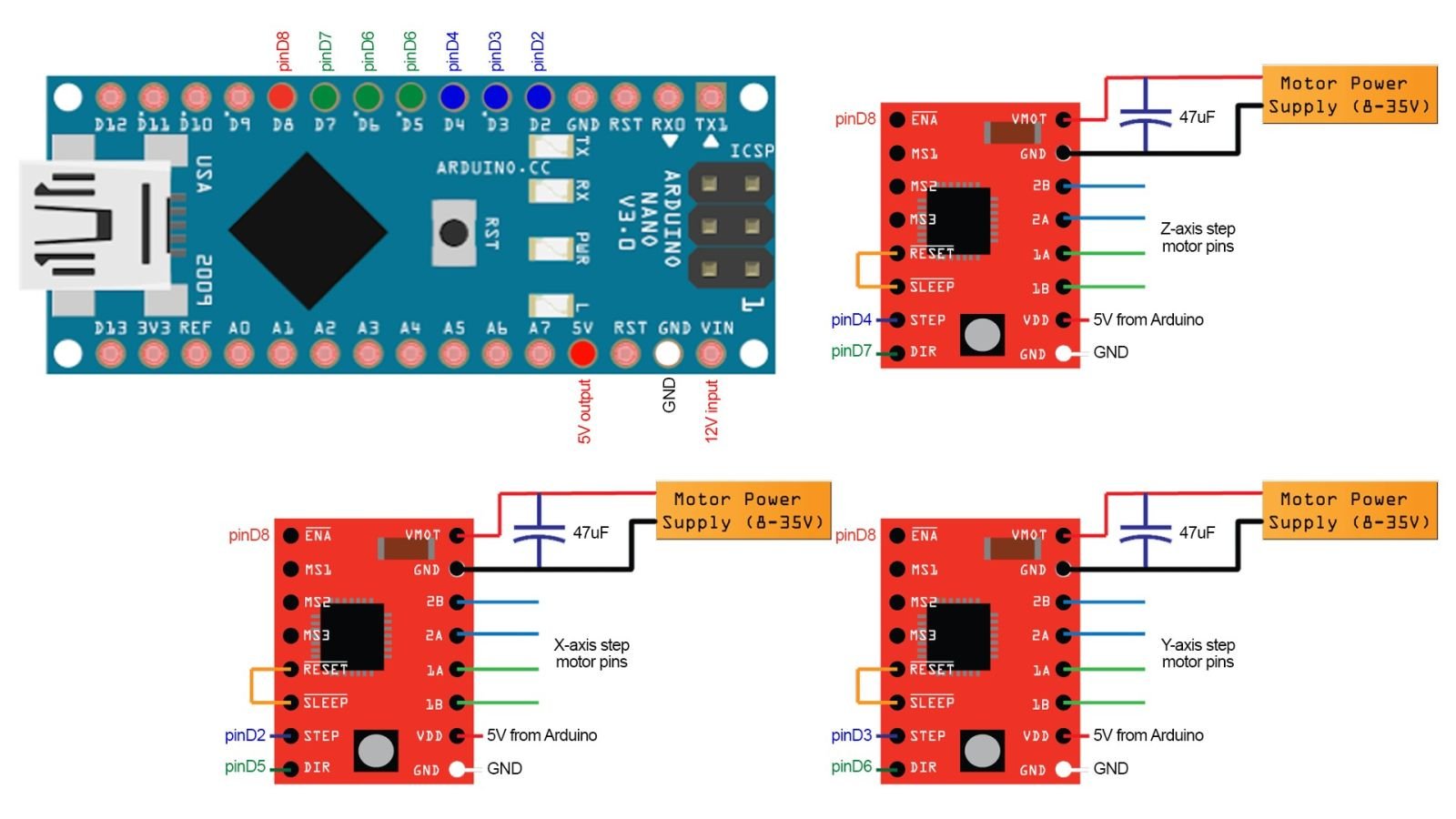

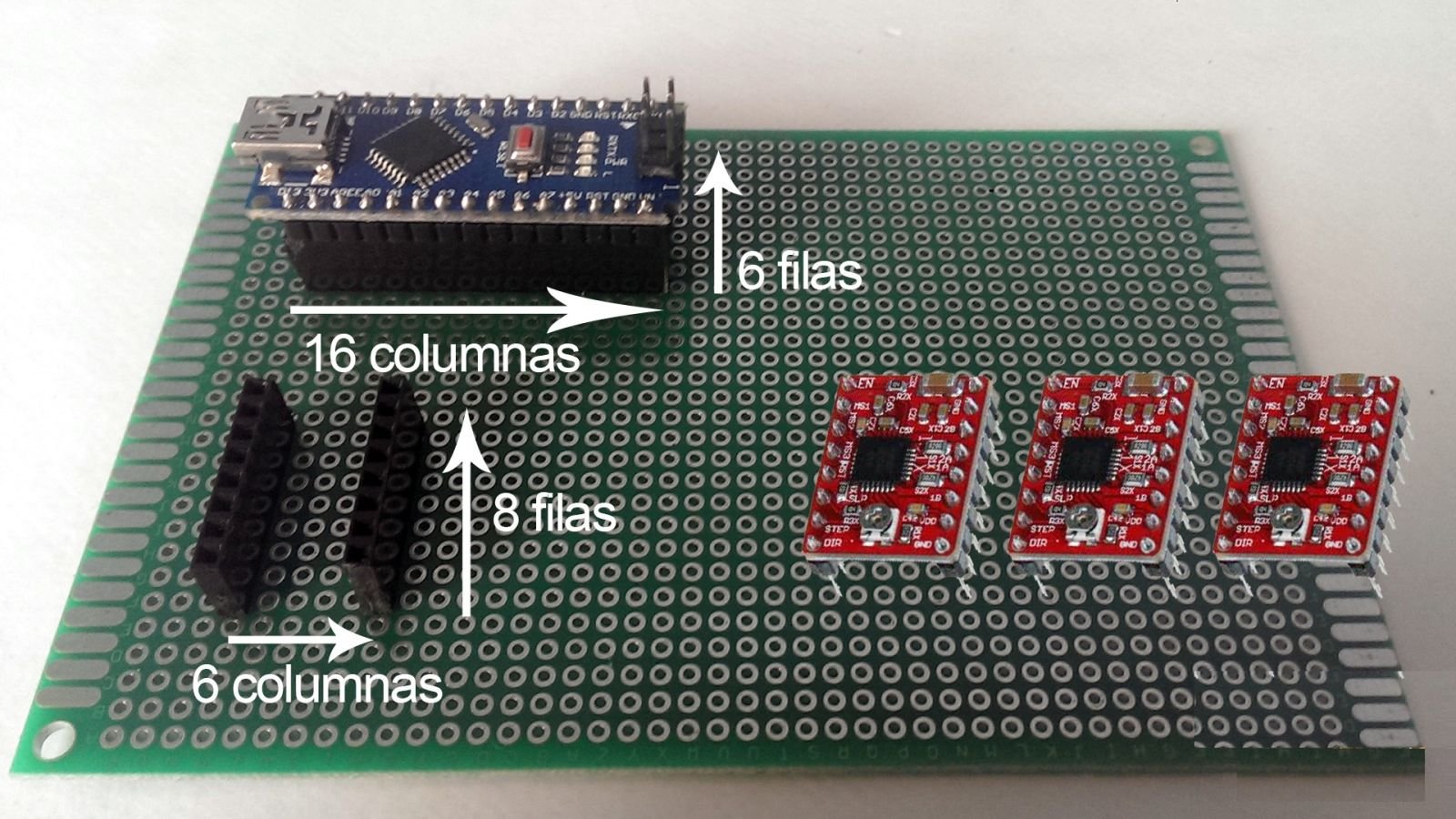

We already have the physical part mounted. We turn now to the part of elctronica. Before programming must mount the circuit for GRBL. Here you can see the complete schematic using a microcontroller Arduino NANO, 3 drivers A4988 stepper motor and few extra components.

In conclusion, Engineer Ali's Mini CNC plotter project, utilizing DVD parts, is an outstanding example of how resourcefulness and creativity can create remarkable and highly functional devices. The Mini CNC plotter project is a cost-effective, eco-friendly, and accessible solution for those seeking to explore the potential of CNC and 3D printing technology. The potential applications of this Mini CNC plotter project are endless, and it has the potential to play a significant role in advancing the fields of engineering and electronics.

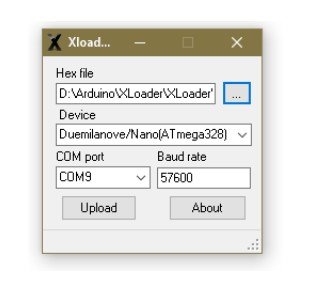

We are now ready to load our GRBL program the Arduino. That cnectamos with the Arduino USB to a PC. The links below will download two programs. The first will Xloader that is the program you use to load the firmwere GRBL the arduino. For that we must download the .hex file below. Download the files and move to the next step.

Dwonloaduniversal G-code Sender 32-bit

Download universal G-code Sender 64-bit

You have already downloaded files and the PC connected to the arduino. The next step is to start the program XLoader

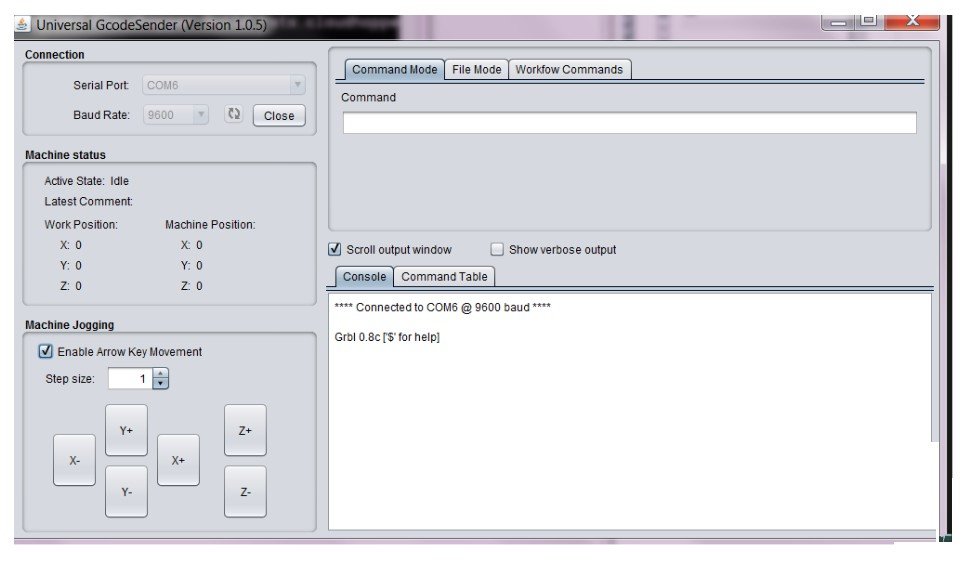

A platform as above photo should appear. We pressed the three ellipses and seek the GRBL.hex file you just downloaded. Entities that what should UnArchiving. Open the file with the .hex Xloader. As a model we choose arduino Demilanove / nano as it is what we use. We choose the COM. In my case my PC has assigned my arduino in COM9. We tightened up and watched as the LEDs TX and RX Arduino serial bus start flashing. Once we uploaded the program we are ready to send code G. For this use the following program that is downloaded heemos Universal G-code Sender. 3 motors connected to the PCB correctly. We feed plate with 12 volts and connect the USB to arduino. Start the Universal G-code Sender.

In the section of the COM connection select it and click open. We observe the console as a communication generated with our arduino. At this moment we start tapping the buttons for manual control engines should move. To test go to the file mode (file mode) and open the following file ejemplo.gcode. We opened it and pressed send and see how the machine began to draw. Do not forget to add a small paper and a pen for drawing.

Posted by Ali Aslan at Saturday 8th of July 2023 11:57:51 AM