Make PCB with Photoresist Film

Project Overview: PCB Fabrication Using Photoresist Film

In this project, we demonstrate the process of creating a printed circuit board (PCB) using photoresist film. This method ensures high precision and is ideal for prototyping or small-scale PCB production. The process involves several key stages, including surface preparation, photoresist application, UV exposure, etching, and finishing. Below is a detailed and professional explanation of each step:

Step 1: PCB Design and Printing

-

PCB Design:

- Use PCB design software (e.g., Eagle, Altium, or KiCAD) to create the circuit layout.

- Ensure the design meets required specifications, including trace widths and spacing.

-

Print the Design:

- Export the design and print it onto transparent film using a laser printer. The black areas represent conductive traces, and the clear areas indicate where copper will be removed.

- For better results, use a high-resolution printer to ensure sharp and precise lines.

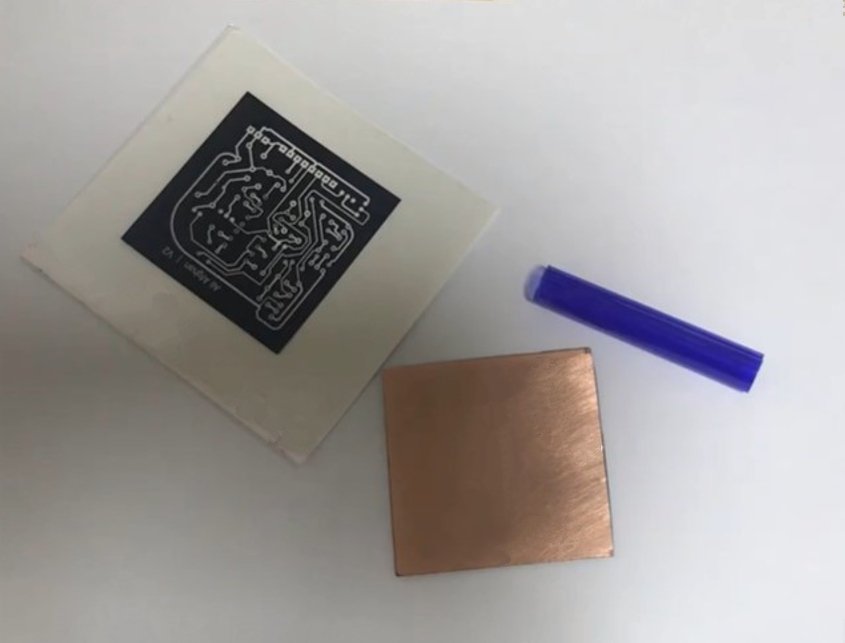

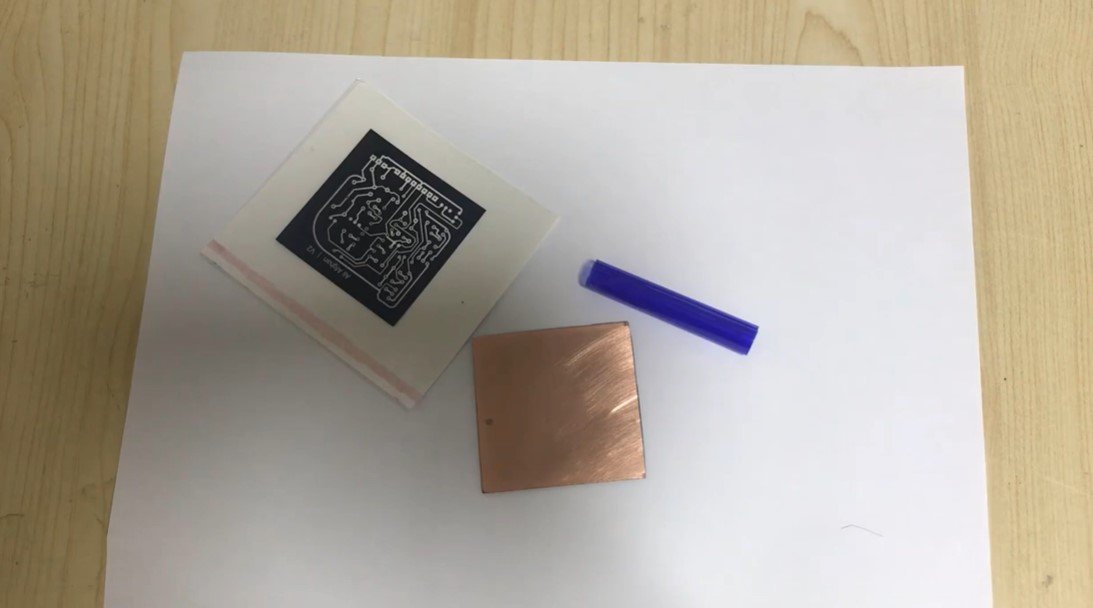

Step 2: PCB Preparation

-

Surface Preparation:

- Start with a clean copper-clad PCB. Sand the surface lightly with fine-grit sandpaper to remove oxidation and ensure smoothness.

- Wash the PCB thoroughly with water and soap, and dry it completely.

-

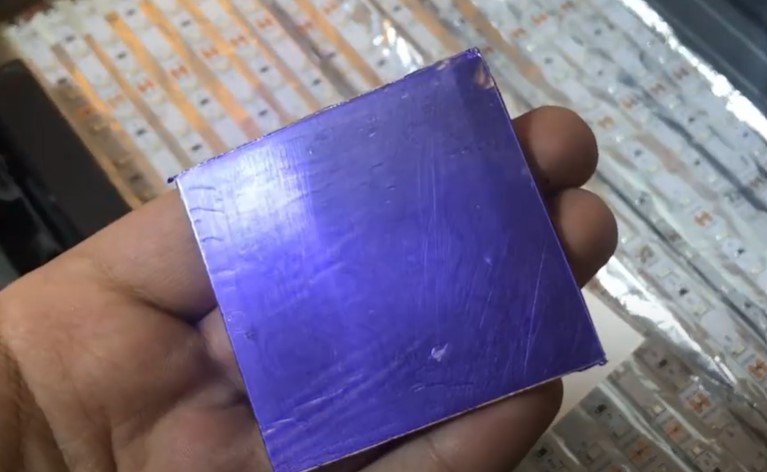

Apply Photoresist Film:

- Separate the protective backing from the photoresist film using adhesive tape.

- Carefully apply the film onto the PCB, ensuring there are no air bubbles or wrinkles.

-

Laminate the Film:

- Use a laminator or apply even pressure and heat to secure the film firmly to the PCB surface. This ensures a smooth and uniform bond between the film and the copper layer.

Step 3: UV Exposure

-

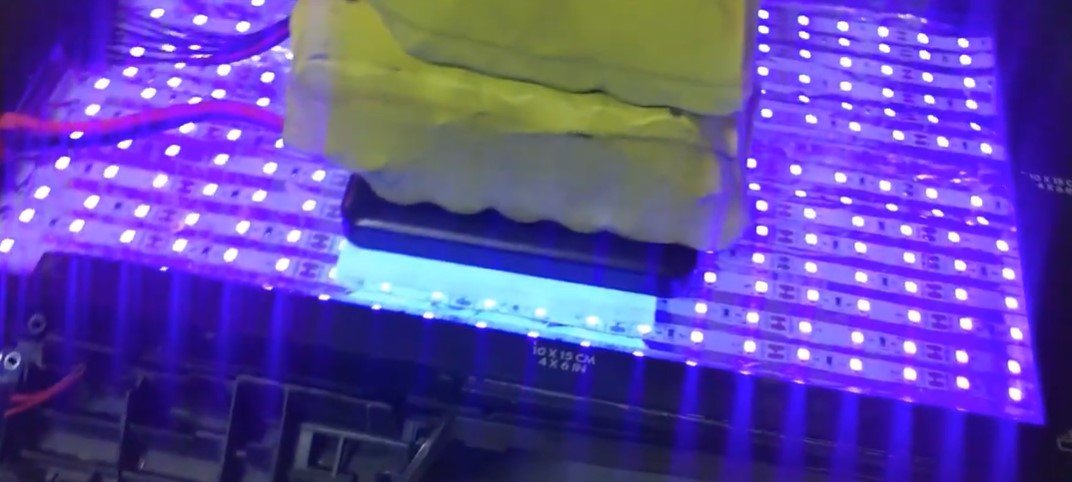

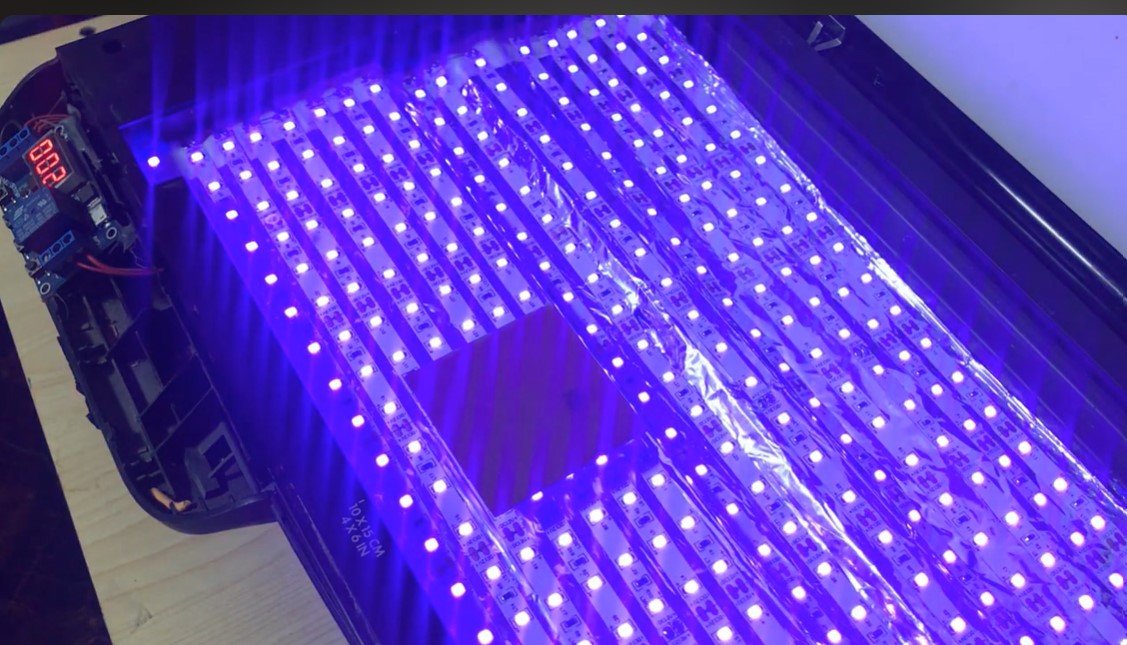

Align the Printed Film:

- Place the printed transparent film over the photoresist-coated PCB, ensuring precise alignment.

-

UV Exposure:

- Expose the PCB to UV light for a specific duration (as recommended by the photoresist film manufacturer).

- The UV light hardens the areas exposed through the clear parts of the film, while the black areas remain unaffected.

Step 4: Developing the PCB

-

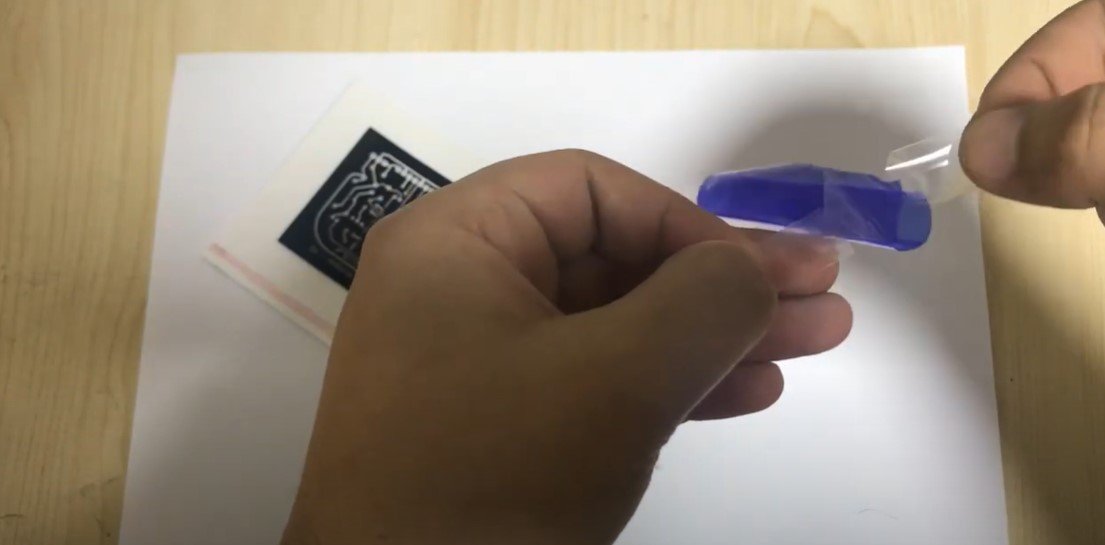

Remove Protective Layer:

- After UV exposure, peel off the top protective layer of the photoresist film using adhesive tape.

-

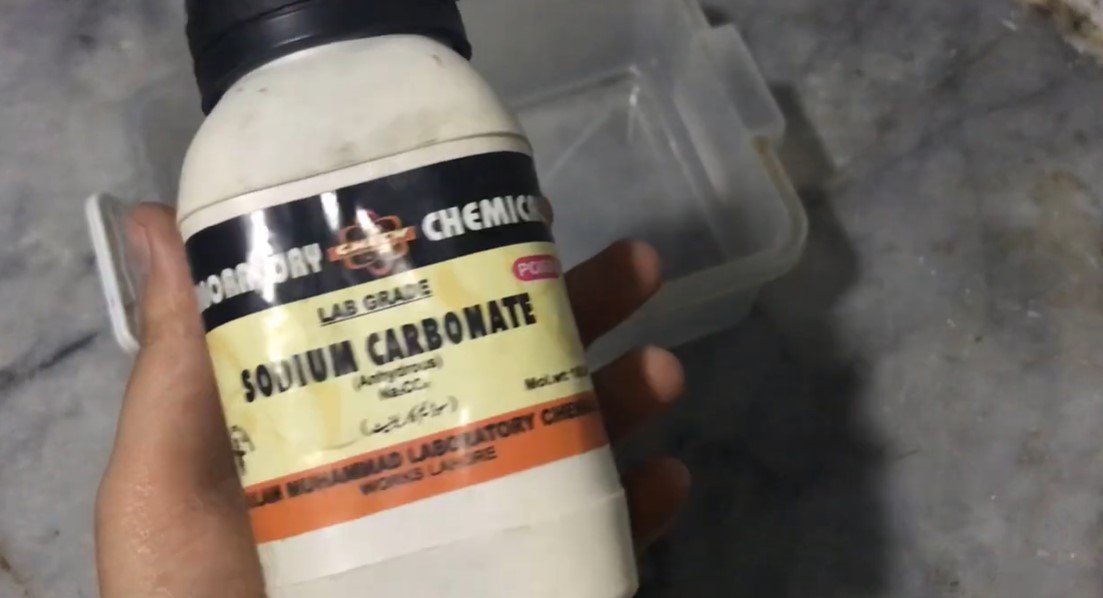

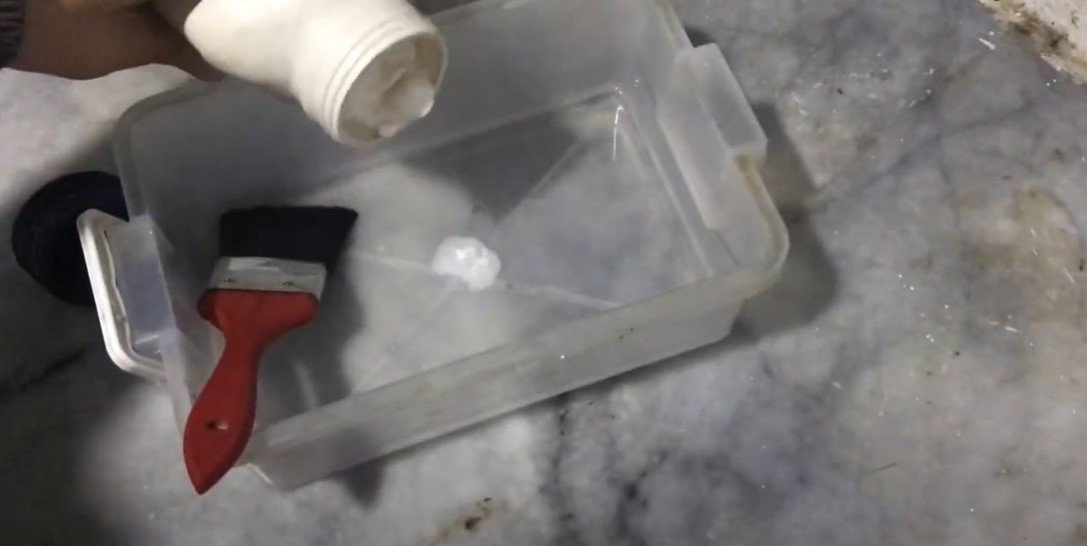

Develop the Image:

- Prepare a solution of sodium carbonate (Na₂CO₃) in water.

- Submerge the PCB in the solution and gently brush to remove the unexposed (unhardened) areas of the film, revealing the bare copper underneath.

-

Final UV Hardening:

- Once the desired areas are exposed, place the PCB back under UV light for additional hardening of the remaining photoresist.

Step 5: Etching the PCB

-

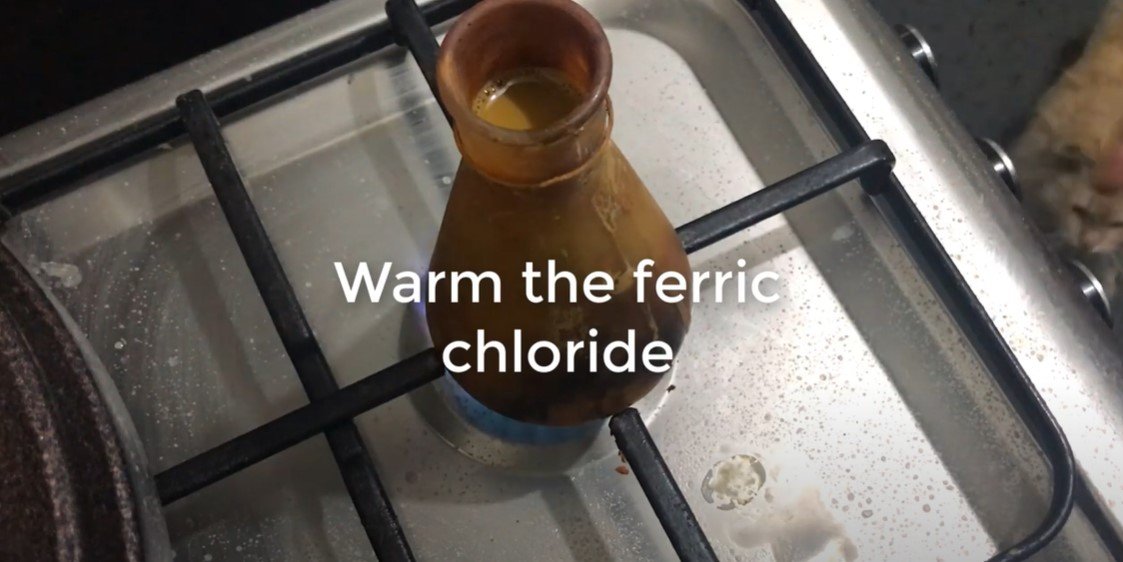

Prepare Ferric Chloride Solution:

- Heat ferric chloride (FeCl₃) solution to improve the etching process.

- Use appropriate safety measures, such as gloves and goggles, as ferric chloride is corrosive.

-

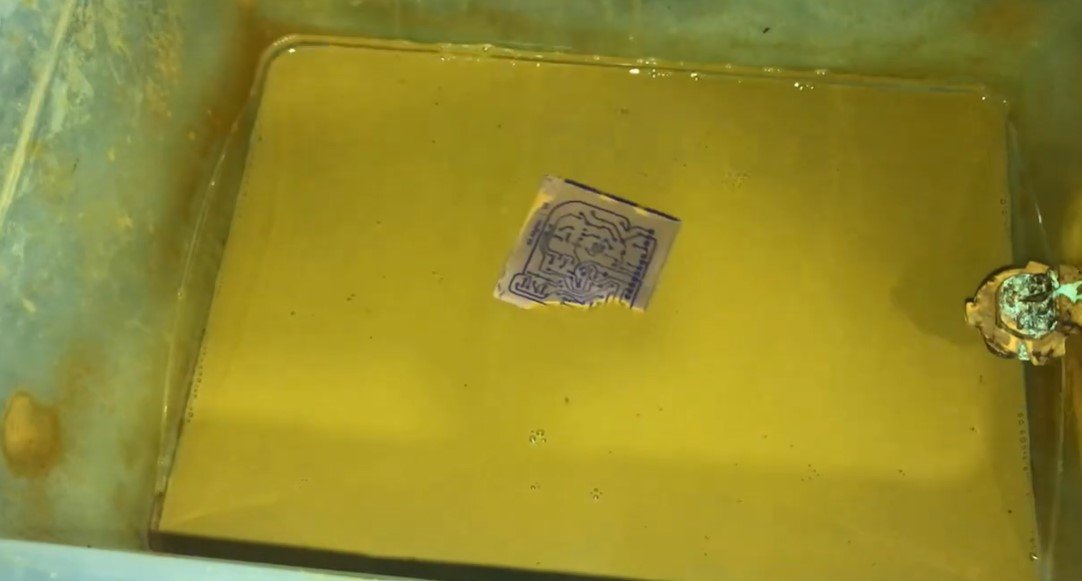

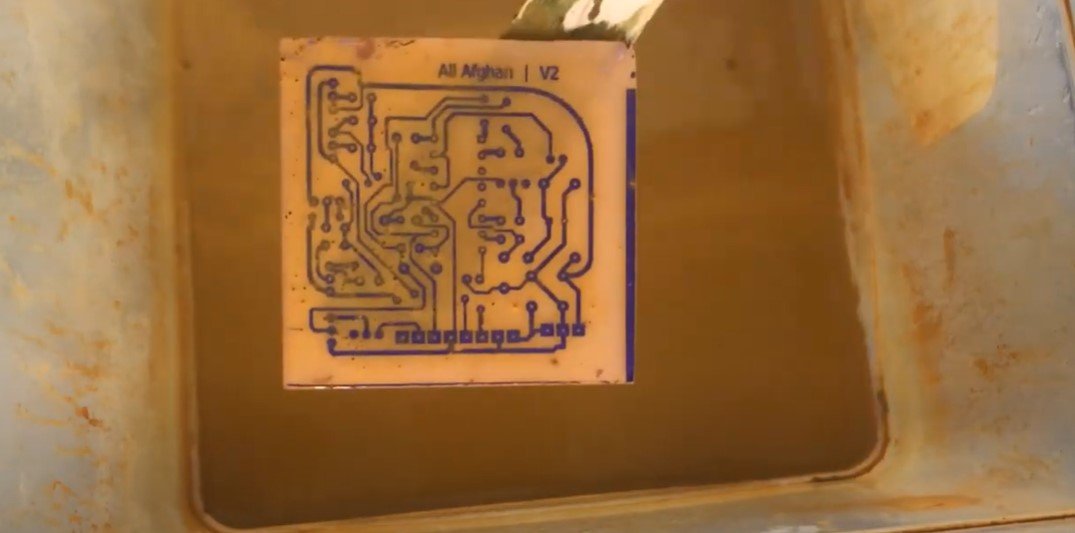

Etch the PCB:

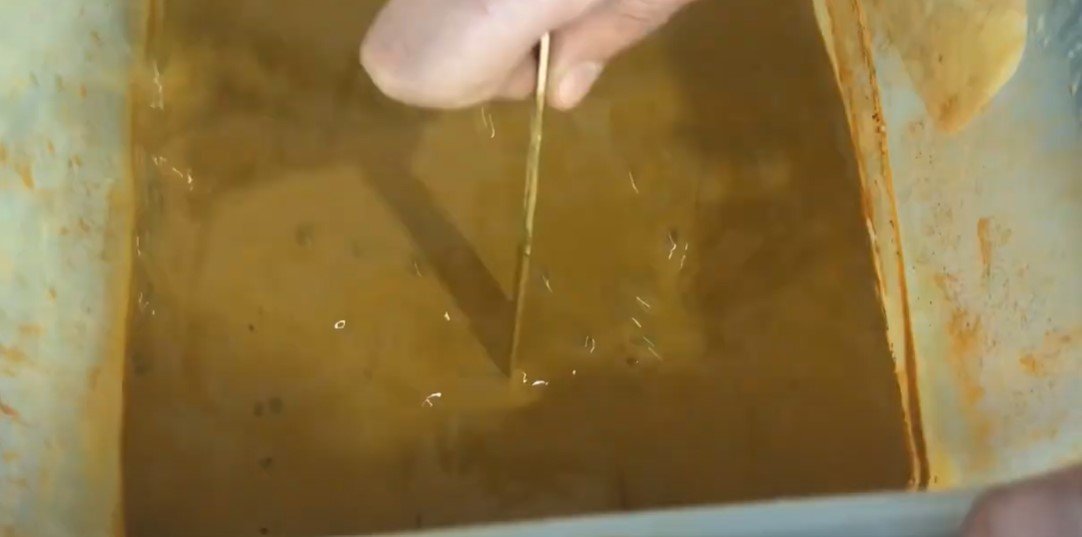

- Submerge the PCB in the ferric chloride solution and agitate gently to speed up the etching process.

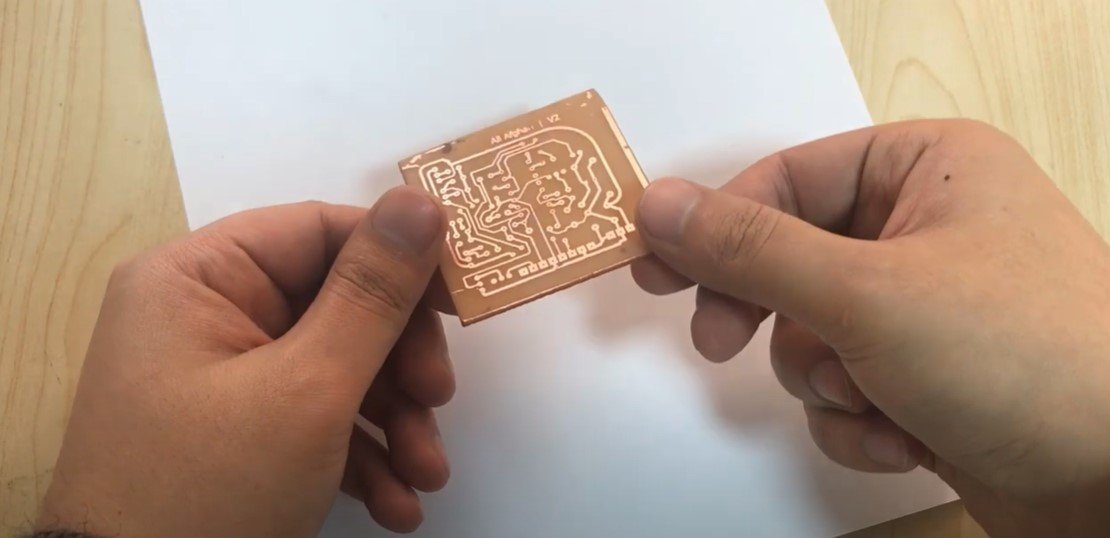

- Continue until all the exposed copper is dissolved, leaving only the traces protected by the hardened photoresist.

-

Rinse the PCB:

- Wash the PCB thoroughly with water to remove any remaining etchant.

Step 6: Removing the Photoresist

-

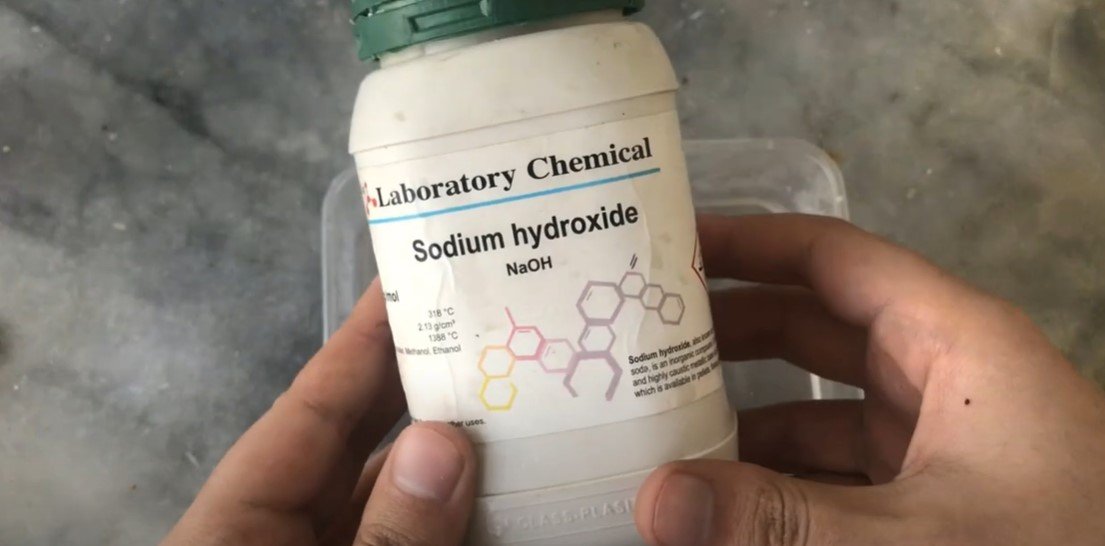

Prepare Sodium Hydroxide Solution:

- Mix sodium hydroxide (NaOH) with water to create a stripping solution.

-

Remove the Photoresist:

- Submerge the PCB in the solution to dissolve the hardened photoresist.

- Wash the PCB with water to reveal the final copper traces.

Step 7: Drilling and Component Soldering

-

Drill Holes:

- Use a precision drill to create holes for through-hole components as per the PCB layout.

-

Component Assembly:

- Solder the components onto the PCB using a soldering iron and appropriate solder wire.

- Check connections for continuity and functionality.

Benefits of Photoresist PCB Fabrication

-

High Precision:

- Photoresist film allows for detailed and accurate trace patterns.

-

Cost-Effective:

- Ideal for prototyping and small-scale production without the need for professional equipment.

-

Customizable:

- Enables easy adjustments to the PCB design for unique project requirements.

Conclusion

Using photoresist film to fabricate PCBs is an efficient and reliable method for creating high-quality boards. By following the outlined steps carefully, you can produce PCBs suitable for a wide range of electronic applications. This process is perfect for DIY enthusiasts, electronics hobbyists, and engineers working on prototypes or small-batch production.

Posted by Ali Aslan at Friday 10th of January 2025 11:40:47 AM